Global Orthopedics Industry Members Meet At Winona Lake Seminar

April 18, 2024 at 5:42 p.m.

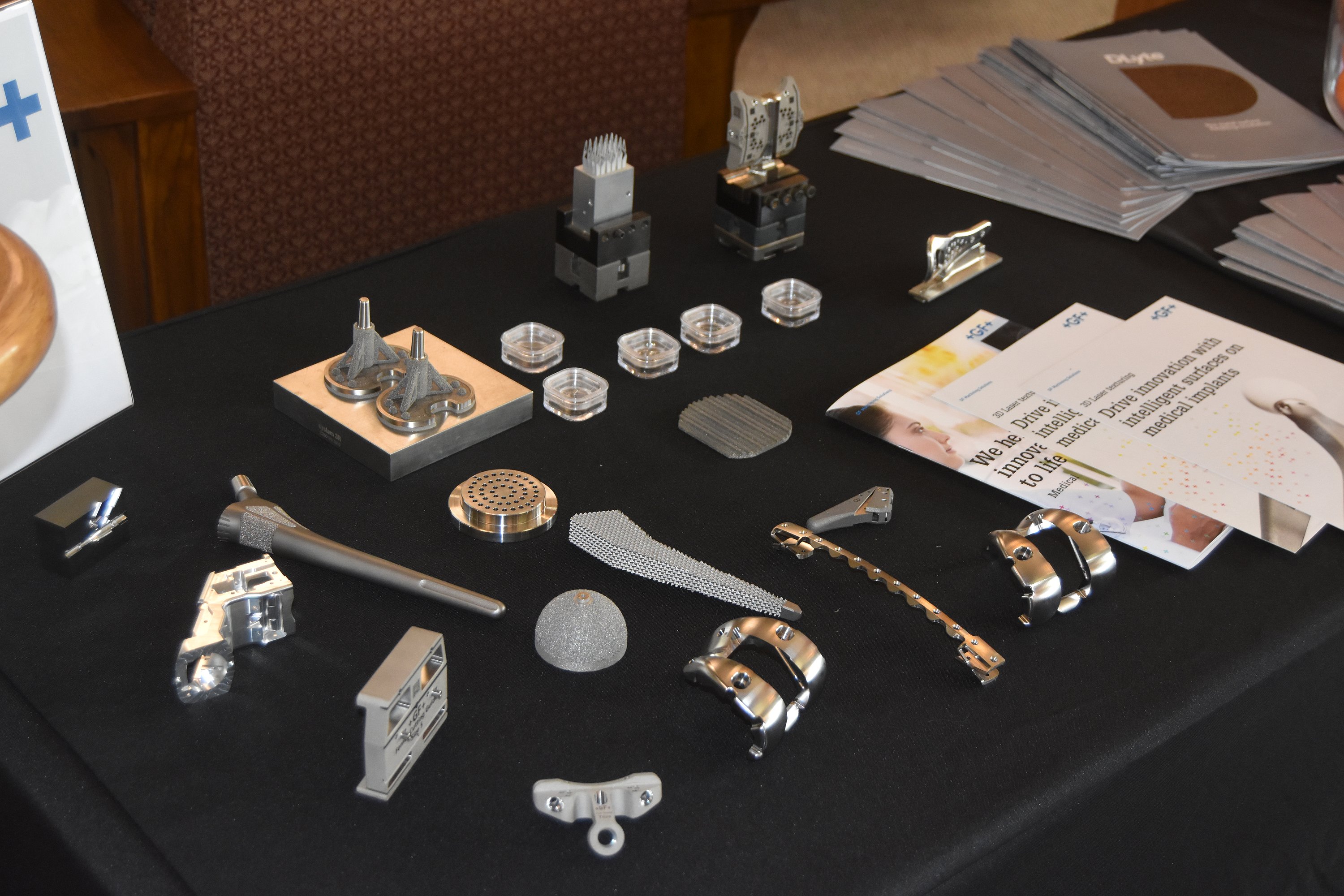

WINONA LAKE — Members of the global orthopedic industry gathered Thursday to share techniques and ideas at a seminar.

The “Efficient Manufacturing of Orthopedic Implants” was hosted by GF Machining Solutions, along with DLyte, Seco, Open Mind and Zeiss.

Avicenne Medical founder Ali Madani came from Paris to deliver the keynote speech, where he gave a report on the industry.

Madani shared that in 2023 the global end-user market for implants had grown to $51 billion, up 6.2% from 2022, and reported that Zimmer Biomet had a 13% share of the market. Madani predicted that by 2030 the market would increase to $72 billion. Madani also shared that Stryker, which he described as a “challenger” company to the main six major companies in the U.S., including Zimmer Biomet, saw growth.

Madani told the audience that some markets were seeing a decrease in average prices due to price erosion.

“According to our forecasts, we believe the average sales price will decrease and continue to decrease,” Madani said, with decreases in the U.S., Europe and more significant in Japan.

“To conclude for the end-user market, opportunity on this market is that companies are able to gain market shares by launching new products,” Madani said.

He also shared challenges for new companies to enter the field, such as regulations and decreasing prices. Madani reported that the seven major orthopedic companies in the U.S. spend $10 billion for manufacturing blunt instruments.

Madani said that one company, Advantech, launched 20 new products since 2018 and 82% of their profits were driven by new products.

A growing market Madani reported for manufacturing was the use of 3D printing. The market growth for 3D and computer numerical control machines was $140 million in the U.S. market, and included an increase from 230 machines used in 2015 to around 1,300 machines by 2023.

Madani also shared that in the top 20 global orthopedic companies, Jabil Healthcare, based in Japan, was first, followed by Tecomet, which has a location in Warsaw.

Following Madani’s speech, GF Machining Solutions Medical Segment Manager Erik Poulsen shared a presentation on milling knee implants.

Poulsen shared that GF Machining Solutions, headquartered in Switzerland, is in partnership with companies such as Open Mind Tech and Seco, working “on understanding the challenges and looking for solutions as to how we can make orthopedic implants more efficient.”

Poulsen explained that the challenge came from a customer who asked if it was possible to go from milling knee replacements to a shorter, two-step polishing process, versus the average five.

“I’ve had the privilege of walking through probably about 15 manufacturing sites in the last four months,” Poulsen said. “And I can tell you that that is a shared goal among almost all manufacturer sites I’ve visited.”

Poulsen shared examples of challenges to machining a knee replacement, such as uneven finished, what Poulsen described as “shadows,” which require hand polishing to remove.

One solution Poulsen offered was replacing ball screw axises with linear motors, that avoid adding bumps while rotating and decrease mechanical wear.

Poulsen said that in a study using a Mikron Mill S-series machine produced by GF Machining Solutions, knee processing was 30% faster in manufacturing, had 30-80% better surface finish and a 20-50% reduction versus the current manufacturing process.

Poulsen also discussed the challenge of “temperature creep,” where temperature changes impacted the final product which can introduce errors of 80 microns.

The solution Poulsen presented was Internal Thermal Composition, which plans ahead for temperature changes. Internal Thermal Composition includes using CO2 to cool machine parts, which is currently being tested in a facility in Germany.

Poulsen said that certain materials, such as polyethylene, react to changes in temperatures, which has to be accounted for.

The event also included time for members of the industry to socialize. Open Mind Tech Managing Director U.S., Canada and Mexico Alan Levine shared that Open Mind Tech “was really pleased to be here at the workshop. We have some really interesting technologies to share for efficiency and safety.”

Levine said Open Mind Tech has one client in Kosciusko County and hoped to connect with other companies.

ACI Machine President Mark Cox shared he was interested to meet people and hear more about automation, and “how that ties to very high end equipment is paramount in where our industry is going.”

Latest News

E-Editions

WINONA LAKE — Members of the global orthopedic industry gathered Thursday to share techniques and ideas at a seminar.

The “Efficient Manufacturing of Orthopedic Implants” was hosted by GF Machining Solutions, along with DLyte, Seco, Open Mind and Zeiss.

Avicenne Medical founder Ali Madani came from Paris to deliver the keynote speech, where he gave a report on the industry.

Madani shared that in 2023 the global end-user market for implants had grown to $51 billion, up 6.2% from 2022, and reported that Zimmer Biomet had a 13% share of the market. Madani predicted that by 2030 the market would increase to $72 billion. Madani also shared that Stryker, which he described as a “challenger” company to the main six major companies in the U.S., including Zimmer Biomet, saw growth.

Madani told the audience that some markets were seeing a decrease in average prices due to price erosion.

“According to our forecasts, we believe the average sales price will decrease and continue to decrease,” Madani said, with decreases in the U.S., Europe and more significant in Japan.

“To conclude for the end-user market, opportunity on this market is that companies are able to gain market shares by launching new products,” Madani said.

He also shared challenges for new companies to enter the field, such as regulations and decreasing prices. Madani reported that the seven major orthopedic companies in the U.S. spend $10 billion for manufacturing blunt instruments.

Madani said that one company, Advantech, launched 20 new products since 2018 and 82% of their profits were driven by new products.

A growing market Madani reported for manufacturing was the use of 3D printing. The market growth for 3D and computer numerical control machines was $140 million in the U.S. market, and included an increase from 230 machines used in 2015 to around 1,300 machines by 2023.

Madani also shared that in the top 20 global orthopedic companies, Jabil Healthcare, based in Japan, was first, followed by Tecomet, which has a location in Warsaw.

Following Madani’s speech, GF Machining Solutions Medical Segment Manager Erik Poulsen shared a presentation on milling knee implants.

Poulsen shared that GF Machining Solutions, headquartered in Switzerland, is in partnership with companies such as Open Mind Tech and Seco, working “on understanding the challenges and looking for solutions as to how we can make orthopedic implants more efficient.”

Poulsen explained that the challenge came from a customer who asked if it was possible to go from milling knee replacements to a shorter, two-step polishing process, versus the average five.

“I’ve had the privilege of walking through probably about 15 manufacturing sites in the last four months,” Poulsen said. “And I can tell you that that is a shared goal among almost all manufacturer sites I’ve visited.”

Poulsen shared examples of challenges to machining a knee replacement, such as uneven finished, what Poulsen described as “shadows,” which require hand polishing to remove.

One solution Poulsen offered was replacing ball screw axises with linear motors, that avoid adding bumps while rotating and decrease mechanical wear.

Poulsen said that in a study using a Mikron Mill S-series machine produced by GF Machining Solutions, knee processing was 30% faster in manufacturing, had 30-80% better surface finish and a 20-50% reduction versus the current manufacturing process.

Poulsen also discussed the challenge of “temperature creep,” where temperature changes impacted the final product which can introduce errors of 80 microns.

The solution Poulsen presented was Internal Thermal Composition, which plans ahead for temperature changes. Internal Thermal Composition includes using CO2 to cool machine parts, which is currently being tested in a facility in Germany.

Poulsen said that certain materials, such as polyethylene, react to changes in temperatures, which has to be accounted for.

The event also included time for members of the industry to socialize. Open Mind Tech Managing Director U.S., Canada and Mexico Alan Levine shared that Open Mind Tech “was really pleased to be here at the workshop. We have some really interesting technologies to share for efficiency and safety.”

Levine said Open Mind Tech has one client in Kosciusko County and hoped to connect with other companies.

ACI Machine President Mark Cox shared he was interested to meet people and hear more about automation, and “how that ties to very high end equipment is paramount in where our industry is going.”